Call us now

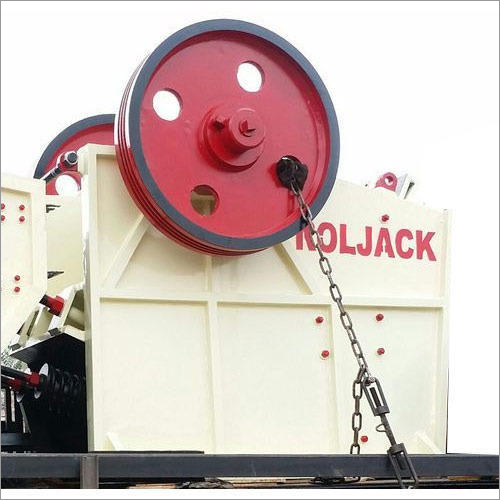

08045817047Single Toggle Jaw Crushers

1000000 INR

Product Details:

- Product Type Single Toggle Jaw Crushers

- Material Galvanized Steel

- Automatic Yes

- Control System PLC Control

- Voltage 220-240 Volt (v)

- Feature High Performance, High Efficiency

- Color White

- Click to view more

X

Single Toggle Jaw Crushers Price And Quantity

- 1000000 INR

- 1 Piece

Single Toggle Jaw Crushers Product Specifications

- Galvanized Steel

- High Performance, High Efficiency

- Yes

- 220-240 Volt (v)

- Single Toggle Jaw Crushers

- White

- 1 Years

- PLC Control

Single Toggle Jaw Crushers Trade Information

- Cash in Advance (CID)

- 30 Piece Per Month

- 30-45 Days

- All India

Product Description

Single Toggle Jaw Crushers are designed to achieve maximum capacity by providing continuous and regular feeding, as well as to hard crush material at a faster rate with less power and less maintenance. These crushers were developed in accordance with the design objectives of the new generation of single toggle crushers in order to achieve the best possible geometry in crushing with rubbing and crushing. Single Toggle Jaw Crushers have a high eccentricity and a very specific crushing angle to reduce maintenance and maximize output.

Superior Crushing Performance

Built to deliver high performance, the Single Toggle Jaw Crusher excels in breaking down tough materials with minimal effort. Its advanced design ensures uniform output while maintaining remarkable throughput, making it ideal for demanding applications across construction, mining, and recycling industries.

Efficient and Automated Operation

This crusher features a fully automatic operation powered by a PLC control system, allowing seamless and user-friendly interaction. The integration of automation boosts efficiency, minimizes manual labor, and helps maintain optimal settings for consistent material processing.

Durable Build and Reliable Support

Constructed using galvanized steel and finished in white, the crusher is both durable and resistant to corrosion. As a product supported by a trusted network of distributors, exporters, manufacturers, suppliers, and traders in India, customers benefit from robust after-sales support and a dependable 1-year warranty.

Specification

|

Material |

Mild Steel |

|

Capacity |

150 ton/hour on close side setting of 150 mm |

|

Brand |

Roljack |

|

Automation Grade |

Automatic |

|

Warranty |

1 Year |

|

Motor Power |

100 HP |

|

Frequency |

50 Hz |

|

Feeding Size |

575 mm |

|

Voltage |

220V |

|

Jaw Size |

36 x 24 inch |

|

Country of Origin |

Made in India |

FAQs of Single Toggle Jaw Crushers:

Q: How does the PLC control system enhance the efficiency of the Single Toggle Jaw Crusher?

A: The PLC control system enables automated, precise control over crusher operations, reducing human intervention. This improves efficiency, ensures consistent material size output, and allows for easy monitoring and adjustments to process settings.Q: What materials can be processed using this galvanized steel jaw crusher?

A: The crusher is designed to handle a wide range of materials commonly found in construction, mining, and recycling industries, such as ores, rocks, and aggregates, due to its sturdy galvanized steel construction and high-performance features.Q: When is it recommended to use a high-performance jaw crusher like this?

A: This jaw crusher is ideal for applications requiring fast and consistent material reduction, especially in environments where reliability and scalability are critical. Use it when handling large volumes or abrasive materials that demand efficiency and durability.Q: Where is this Single Toggle Jaw Crusher manufactured and distributed from?

A: The crusher is manufactured, distributed, exported, and supplied by established companies based in India, catering to both domestic and international markets through a wide network of industry partners.Q: What is the process for setting up and operating this crusher?

A: Installation involves connecting the unit to a 220-240 Volt power source and integrating the PLC control system for operational commands. Initial settings and safety checks are performed using the automated interface, allowing even first-time users to operate the equipment effectively.Q: How does the automatic feature benefit daily operations?

A: Automation via PLC control streamlines operations, reduces manual workload, minimizes operational errors, and ensures higher throughput, ultimately saving time and labor costs for operators.Q: What warranty and support can customers expect with this jaw crusher?

A: Customers receive a 1-year warranty with comprehensive after-sales support provided by the network of distributors, exporters, manufacturers, suppliers, and traders in India, ensuring reliable performance and prompt service whenever needed.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese